Description

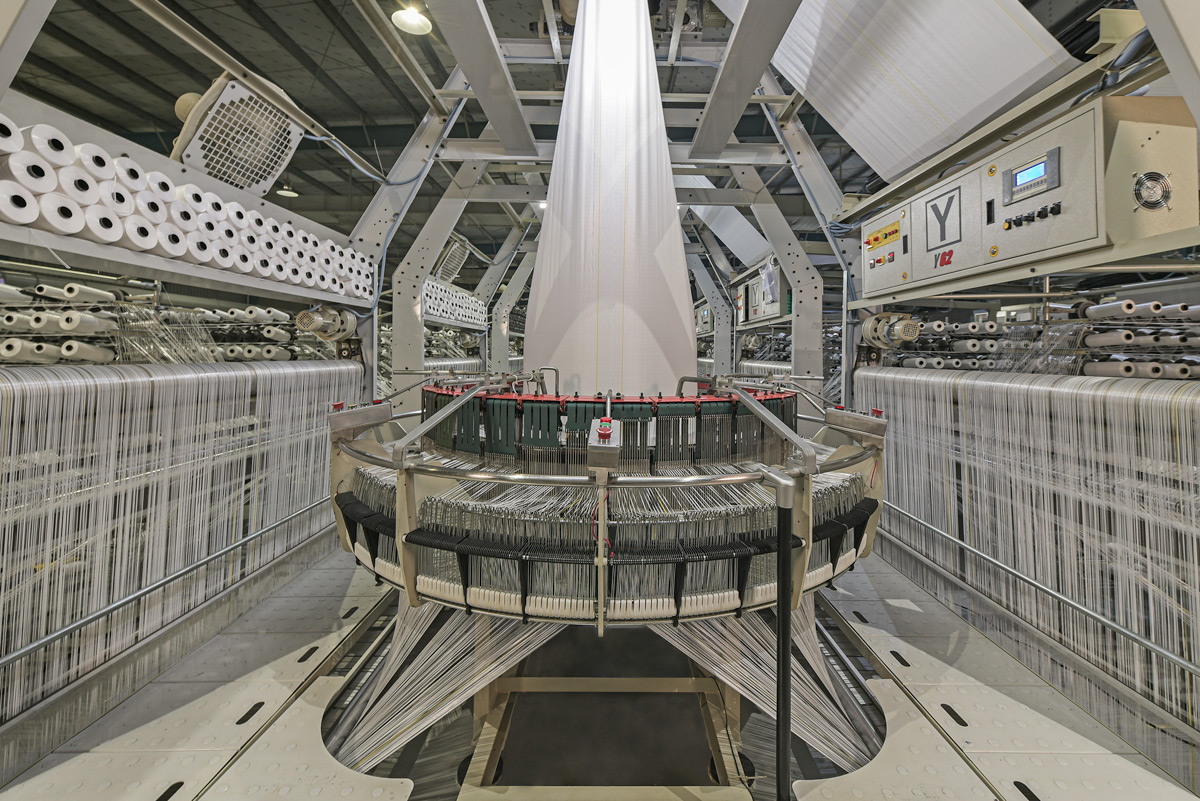

Your Equipment Solutions offers a wide range of circular looms for weaving light to heavy weight tubular or flat PP/HDPE fabrics for a variety of end applications with highest standards of precision, usability, and productivity.

Our loom ranges from 4 shuttle to 12 shuttle for a vast range of packaging applications such as narrow fabric, cement, fertilizer, polymer granules, chemicals, grains, animal feed, wide width fabric for Jumbo bags (FIBC’s), tarpaulins and geo & agro textiles.

It has advantages of the latest technology : higher operating efficiencies, excellent weaving quality, lower wastage, lower energy consumption, low maintenance etc, making our looms the best choice for customers.

Main Features

- Production speed up to 1100 ppm in Y6.

- High efficiency.

- Wear and tear resistant.

- Outstanding fabric quality from 50 to 200 g/m2*.

- Weft tape width up to 5 mm.

- Large warp and weft tape packages.

- Energy-saving AC drives.

[* depending on tape quality, fabric width and density]

Technical Specifications

| Machine Model | Y4 | Y4L | Y6 | Y61 | Y62 | Y62D | Y8 | Y12 |

| Working Width, Double Flat | 31 - 61 cm | 31 - 72 cm | 48 - 71 cm | 61 - 114 cm | 91 - 140 cm | 91 - 140 cm | 165 - 211 cm | 228 - 280 cm |

| No. of Shuttles | 4 | 4 | 6 | 6 | 6 | 6 | 8 | 12 |

| Creel Capacity ** | 504 | 576 | 576 / 720 | 936 | 1152 ** | 2112 | 2400 | 2880 |

| Weft Insertion Rate ** | 720 | 400 | 1100 | 900 | 840 | 600 | 660 | 660 |

| Warp/Weft ID ** | 35 mm | 35 mm | 35 mm | 35 mm | 35 mm | 35 mm | 35 mm | 35 mm |

| Warp/Weft Core Length ** | 218 mm | 218 mm | 218 mm | 218 mm | 218 mm | 218 mm | 218 mm | 218 mm |

| Warp Bobbin Dia. (Max) | 130 mm | 130 mm | 130 mm | 130 mm | 130 mm | 130 mm | 130 mm | 130 mm |

| Weft Bobbin Dia. (Max) | 110 mm | 110 mm | 115 mm | 115 mm | 115 mm | 115 mm | 115 mm | 115 mm |

| Fabric Roll Diameter | 1200 mm | 1200 mm | 1200 mm | 1200 mm | 1200 mm | 1200 mm | 800 mm | 800 mm |

[* Actual speed varies depending on Processing Parameters]

[* Special Versions on Request]

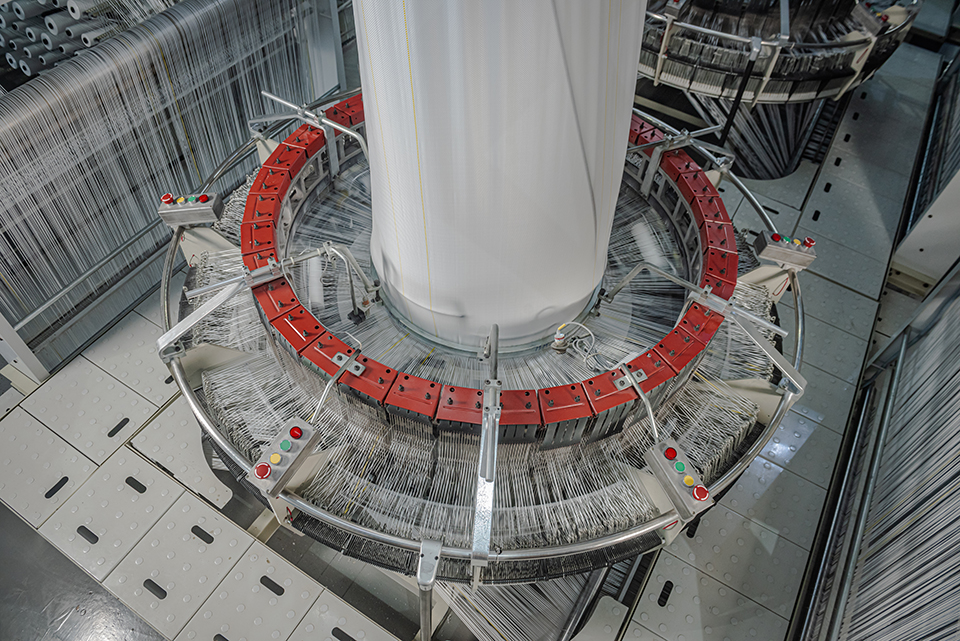

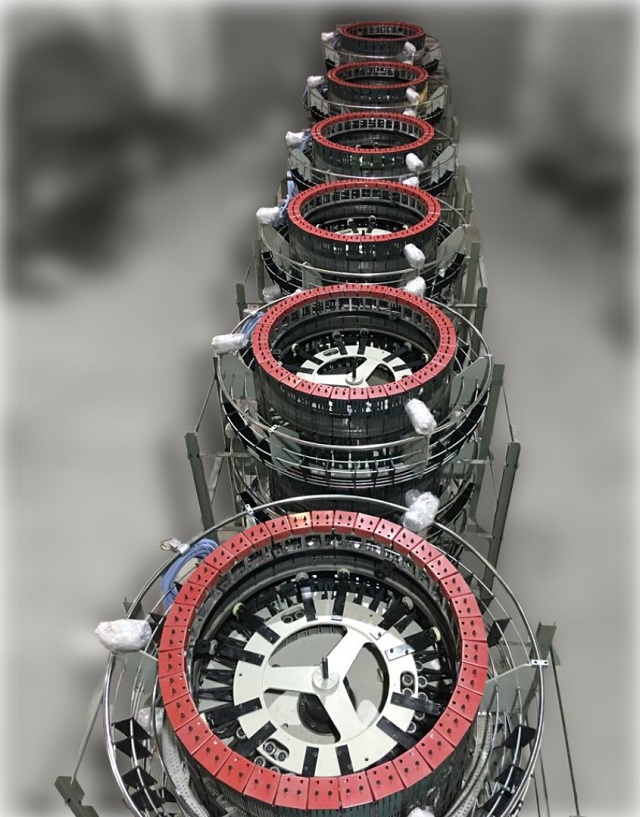

Central Portions

Our dedication to the woven sack industry continues by supplying a quick changeover of the main part in a circular loom: The Central Portion, which is the heart of the machine. We specialise in changing over old circular looms (any model / make) to our latest generation circular looms, thereby giving an instant boost in production, reduced power consumption, better space savings & lower spares consumption.

This saves our customers the cost of upgrading to new looms, by extending the life of the current machines, at the same time ensuring easier operation for the weavers.

Central portions can be changed in any of our above models.